You could mistake it for a heritage attraction, and in a way, it is. But it’s also a thriving business that employs 32 people, and its distinctive textile patterns have found enthusiastic fans everywhere from the United States to Japan.

On a weekday morning, the place is busy, and holidaymakers are drinking coffee in the sunshine outside the mill café. The shop is piled high with throws, cushions, and all sorts of other products that have been made with Melin Tregwynt cloth. A customer is holding a blanket up to the light to see its colours and strokes it ever so gently: textiles are tactile.

There has been a mill on the site since the 17th Century, and it’s one of a handful of businesses that survive from a time when almost every Welsh valley had its own woollen mill. While tribulations of the 20th Century put paid to most, Melin Tregwynt found a way through – and today, it’s a tradition that visitors are willing to travel to see. There’s a magic to the way wool turns into cloth.

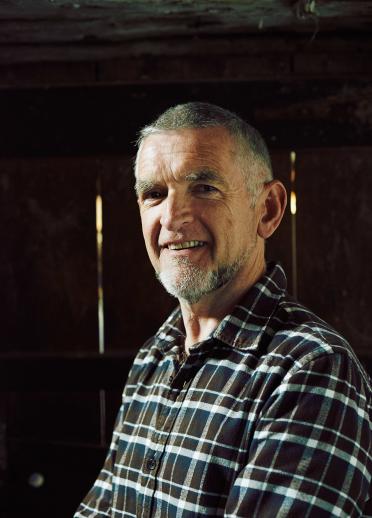

Current owner Eifion Griffiths explains that the business was started by his grandfather, Henry. He bought the property in 1912, paying £760 at auction, and his business model was a simple one. The mill’s raw material was wool produced on nearby farms, and it sold its products close to home.

Eifion says: "It all happened in a small area. Often, sales were made on a barter basis. Looking back at old accounts, we found one record of a farmer who swapped a motorcycle for a new suit."

His father, Howard, took the reins in the 1950s. Eifion trained to be an architect, but returned to Pembrokeshire to work with his father in 1979. "Dad was a great businessman, but he wasn’t that bothered about design, or marketing," he says. "I cared deeply about both - so we worked well together."

Fast-forward to today. Melin Tregwynt is still as grounded in its small corner of Wales, but many of its customers are far, far away. So how did that come about?

The essentials are unchanged. Over the clatter of machinery in the weaving room, Eifion explains the process that produces the mill’s characteristic double cloth, or 'Welsh tapestry'. Two layers are woven together to create a fabric that’s durable, with bold areas of pattern. It’s a technique that has been around since the 18th century, and it’s an antidote to digital designs that can simply be transferred on to any fabric.

It’s no surprise that the most-photographed area of the mill is the shelving that’s loaded with cones of different-coloured yarn. Each is labelled, and many of the names evoke nature: there’s catkin (pale green), shrew (an understated brown) and cornflower (a cheerful blue).

Recent collaborations have helped carry the name of Melin Tregwynt far from home. Double-cloth fabrics are now offered by the Japanese retailer Muji in stores throughout Japan, China and Europe. Eifion and his team also worked with the Welsh design company Smorgasbord to create a cloth for the Cambrian Hotel in Adelboden, Switzerland. 'Cambrian Check' uses colours chosen to reflect the forests and alpine meadows that surround the hotel.

We’re definitely a somewhere business as opposed to an anywhere business."

For Eifion, the key to Melin Tregwynt’s success is its Welsh identity and strong sense of place. "We’re definitely a 'somewhere business' as opposed to an 'anywhere business'," he says. "We’re rooted in where we are, and it’s what sets us apart."